BMC is a ready to mould glass-fibre reinforced thermoset polymer material primarily used in injection moulding. Based on mixing strands of chopped fibers, styrene and initiator and filler mixed with unsaturated thermoset resin. It is produced in bulk or in logs.

Due to the shorter fibre length, BMC is well suited to injection moulding where it flows freely into the smallest cavities, making it suitable for the most intricate parts. The higher inorganic filler load guarantees very high temperature resistance and an extremely good surface appearance, which is why BMC is commonly used for headlamp reflectors and appliances requiring good aesthetic and high heat performance.

At IBV Hungária Kft, we provide to our customers excellent quality and mechanical properties on a 200-ton Krauss Maffei injection molding machine. With this machine, we can produce a number of products made by thermosetting injection moulding, which we intend to provide for different industry fields.

DOMESTIC APPLIANCES

Applications:

– Iron heat shields

– Coffee machine components

– Microwave ware

– White goods components

INJECTION MOLDING

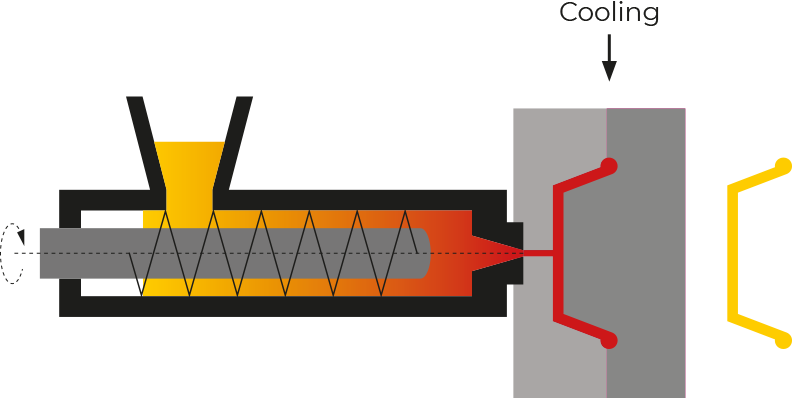

Injection moulding is a continuously developing and expanding industry. The technology is widely used for plastic products manufacturing with the most precise process possible. The principle is that the polymer melt, which has been heated to a low viscosity liquid by heating above the melting point – is “injected” at high speed through a narrow inlet into a closed die – and in this closed die any shaped (3D) part, practically waste-free, with plastic shaping, high dimensional accuracy is formed.

MATERIALS USED

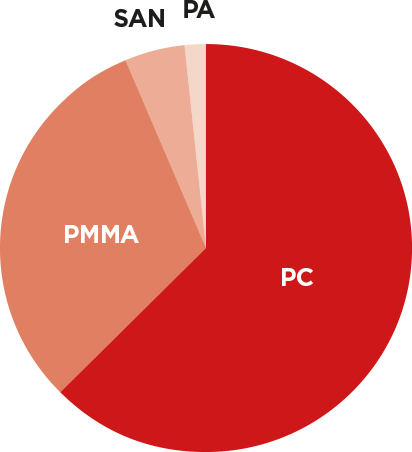

Injection molding is a high-precision and highly productive component manufacturing. The size limits of the manufacturability are extremely wide. The weight of the manufactured product can be several kilograms on an injection molding machine of the right size. It is mainly used for thermoplastic polymers, typically PE, PP, PS, PVC, PMMA, ABS, POM, PC, PA, SAN nevertheless the process developed for materials can also be used in the processing of non-thermoplastic polymers.

Manufacturer | Clamping force (t) | Fastening points |

|---|---|---|

Engel | 1300 | 2200×1990 |

Husky | 1000

| 1840×2070 |

Husky | 1000 | 1840×2070 |

Engel | 900 | 1850×1810 |

Engel | 90 | 730×420 |

Engel | 90 | 730×420 |

Engel | 25 | 470 x 280 |

© 2024 IBV Hungária Lighting and Plastic Processing Kft.